A Guelph company looks to be behind the next generation of rechargeable lithium-ion batteries.

And the premise of these batteries could have long-lasting effects, as Ontario ramps up production of electric vehicles.

Solid UltraBattery Inc. on Hanlon Creek Boulevard is developing the next level of lithium-ion batteries, with the goal of making them longer lasting than what is out on the market.

The first battery batch, a 19 layer 5 Ah – amp-hours, or the unit of measurement for a battery's energy capacity – pouch cell pack was fabricated last May.

These batteries are just a bit bigger than a floppy disc, fairly lightweight and flat. Coin cells are also being produced, similar to what you would see on store shelves for watches and small toys.

They use composite electrolytes “to enhance cycle life and battery stability,” along with the lithium metal to fabricate advanced battery cells.

“Building the battery is one of the harder things in engineering to do,” said V-Bond Lee, the CEO of Volt Carbon Technologies, the parent company for Solid UltraBattery.

“It’s not just engineering, it’s processing, there’s just so many steps, so many ways a battery can go wrong.”

These batteries are being geared toward powering small drones and unmanned aerial vehicles.

“Nowadays, drones are good for anywhere between 25 and 45 minutes of flight,” Lee said. “We’re looking to try and improve the ranges and flight time by 20 to 30 per cent.”

Since acquiring Solid UltraBattery from University of Waterloo professor Zhongwei Chen in 2021, Volt has been slowly building its Guelph operation.

The purchase also came with the IP for the battery technology.

Rocks containing graphite are processed at a facility in Scarborough. The graphite particles then get used as part of developing these batteries.

The 10,000 square foot facility includes office space and a small lab, as well as a large empty production room.

The plan is to replicate the lab setup in the plant to begin manufacturing batteries, but Lee wasn't able to offer a specific timeline at the moment.

Results have been promising thus far. He said Solid UltraBattery could barely get 50 charges for the cycle life out of its batteries when the plant first started up.

That number has now surpassed 600 cycles.

“To be considered for electric vehicles, that number is around 800 to 1,000 cycles, no less than 80 per cent loss in capacity over its lifetime,” Lee said.

According to its website, the hope is to get batteries to exceed 800 cycles by January 2025.

But don’t get it twisted: these are not batteries for automobile use.

“We may be licensing some of our technology in automotive,” Lee said. “But we’re not a giga-factory here, we’re a mega-factory.

“Building a big pack like that for vehicles is a tremendous undertaking, so we feel we’re better able to handle the smaller packs to more specialized applications.”

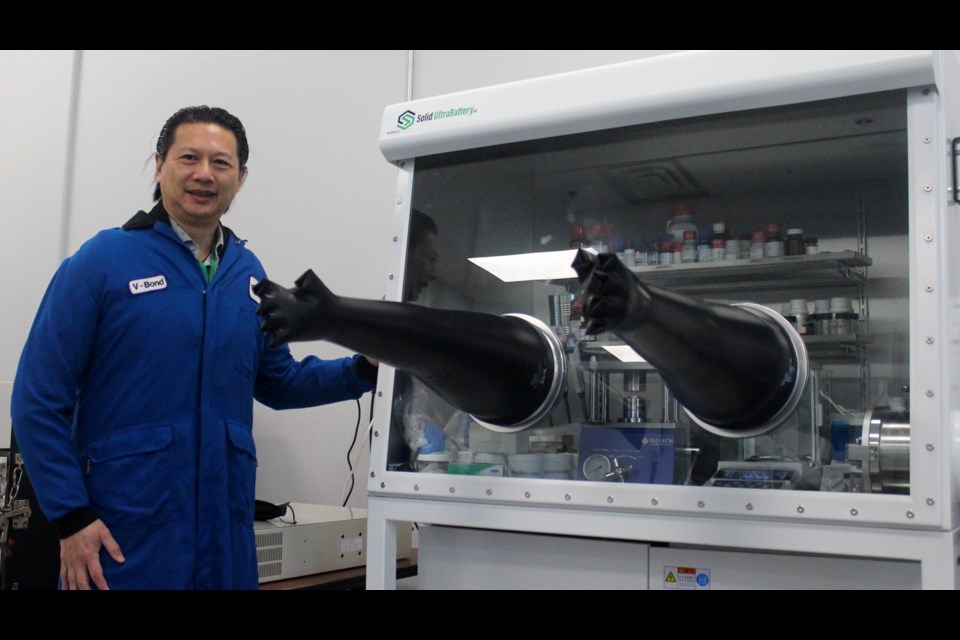

Inside the lab, there are confinement chambers that have very little oxygen and moisture levels.

“That’s an environment where you can assemble batteries without any oxidation of the lithium metal, as well as any potential reactions that may occur,” Lee said.

“The chamber gets filled with argon, and the operators would put their hands into (rubber) gloves (connected to the chamber), and they would do their work in that type of environment.”

Lee added seven workers are currently with the company in Guelph.

The intent is to grow over time to 25 workers.

“There’s not a lot of this work in Canada. The resources you need are very unique,” he said.

“We’re actually developing batteries and battery technology. A lot of it is done in the (United) States, or in Asia.

“It’s good to have this type of resources here because not only is it good for us in terms of having good technology, but it’s also good for growing the workforce, growing the skill.”